Standard

Conveyors

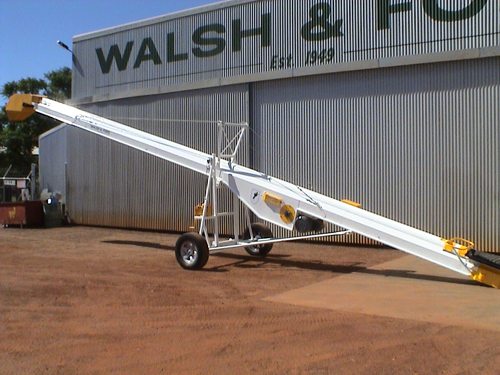

Walsh and for have been manufacturing barrel belt conveyors from 1980’s onward giving us the experience and know-how to produce a product that is robust, functional and adaptable to meet any conditions.

Specifications

Call us for any special requirement or features.

Features

- Manufacturing Barrel Belt Conveyors from 1980’s onwards.

- Standard size 9″ diameter & 11″ diameter. Custom build in sizes above and below.

- Petrol/Diesel Electric or PTO versions.

- Minimum barrel thickness 2.5 mm / 12 gauge.

- Unique skirt design prevents dust accumulation.

- Large strong undercarriage for grain delivery to 27º angle plus dump site building & retrieval.

- Pulleys cast iron with steel taperlocks.

- Built to strip down if tail crushed by semi trucks.

- Hoist, lift arrangement superior to wire rope / pulleys.

- ‘Drive Around’ hubs are lock in / lock out. Similar to 4 wheel drive vehicles, far more superior to ring gear / pinion or chain sprocket drives.

- Return rollers 60.3 diameter with CNC lathed housings inserted into pipe for long life.

- Standard or low profile hoppers available that clip onto unit.

- 180º rollers full adjustment at housings to allow for precise belt adjustment.

- Fuel tanks removable for refilling.

- Belt guards are meshed for viewing and prevention of vermin build up.

- Conveyor is fully self cleaning plus ‘Drive Around’ units allow for full blow down due to their unique tail ram action.

- Option of stainless steel with powder coat frames and two pack finish for use in fertilizer handling.

- ‘Drive Around’ system allows for one man operation of unit.

Photos

We are here to help